Frequently Asked Questions

A totally flawless natural product such timber is extremely rare. If you look very closely at any piece of internal joinery, you can find minor blemishes such as knots, raised grain and minor surface imperfections and varying colour and grain structures. When viewing our products, this should be done standing 2 meters away, with the full doorset being taken into consideration and a not a close-up isolated image.

All surfaces should be viewed in daylight from distance of 2m and not by shining artificial light on the surface. Wall lights and / or uplighters should be switched off.

Timber surfaces may show limited raised grain, and the colour and texture may also vary as veneer is a natural product so colour and grain will vary from batch to batch. Please note that veneers will change colour over time due to natural and artificial light, lighter veneers will darken, darker veneers will lighten.

Products sold as “Paint Grade” are primed only to be site finished. Site finished products will require preparing before finished coats are applied to achieve the desired customer finish.

Site decorated or site finished items such as architrave, glazing beads may have a different finished appearance from components that have been manufactured in a factory environment.

Drying and shrinkage of timber may cause cracking of the paint finish where joints occur in the woodwork.

Resin can exude from knots, causing discolouration of paintwork even though modern primers contain a compound to prevent this.

Hanson and Beards Limited are a third-Party certified fire door manufacturer and our area of expertise lies in the manufacture and fabrication of timber fire doors and door sets only.

Our installation guidelines provide guidance based upon the requirements of BS 8214:2016 for fire door installation and fire stopping requirements.

We strongly recommend that in all instances, the use of third party approved installers are sought to fit our products who will work in accordance with the installer scheme requirements and our fitting guidance documents.

We have no control over the accuracy of the installation process, and it is the sole responsibility of the installer to ensure that fire doors and door sets have been installed correctly.

Hanson and Beards Limited are not qualified to make any assessments or provide opinions on the suitability of other building fabrics or building elements such as structural opening load capacities, suitability of partitioning systems, specialist fixing types and methods or fire containment strategies for any building items other than those supplied and fitted directly into our timber fire doors and door sets.

Advice on anything other than the door set fabrication and the installation guidance, must be sought from specialist qualified sources.

How to do a Professional Inspection:

When inspecting toughened, laminated or coated glass, one should stand no less than three meters away from the glass at 90° whilst looking through the glass and not directly at it. Inspections should be carried in natural daylight but not looking directly towards the sun. Inspections should exclude a 50mm wide permitter around the edge of the glass.

What to Expect when Inspecting glass:

Toughened, laminated or coated glass is acceptable if the following are neither obtrusive nor bunched:

- Bubbles or blisters

- Fine scratches up to 25mm long

- Minute particles

Defects such as smears, fingerprints, or other dirt on the faces of the glass are unacceptable, if they are visually disturbing.

The life expectancy of Our Internal Doorsets is 30 years subject to correct installation and maintenance carried out directly in line with our installation and O&M information.

Life expectancy will be reduced if the doorsets are misused, located in very high traffic areas such as cross corridors without any means of hold open support or damaged through severe collision and impact.

Failure to carry out routine maintenance to items such as hardware and intumescent seals will also reduce the product life expectancy.

Products identified with this level of certification (RED or GREEN) may not be fully prepared and therefore require further processing on site before the leaf is ready to be hung for the frame.

Further processing must be carried out directly in line with Hanson and Beards scope of certification.

Products identified with this level of certification (SILVER) require no further preparation or processing however it is permissible to fit hardware during the final installation process.

The final assembly and installation of the doorset should be completed with simple tools only, such as a screwdriver. (Only doorsets supplied with Synthesis Hardware meet “Silver Plug” status)

Q-Mark Fire Door Installer Certification

To demonstrate the doorsets have been installed under the supervision of a Q-Mark Approved Installer the doorset must be included within the Record of Installation Activities and a GOLD label affixed to the doorset (Typical Trada detail)

GOLD plugs along with the gold label can only be fitted to a SILVER certified factory hung doorset.

Hanson & Beards recommend that the doorset Installer is certified by a recognised third-party UKAS assured installation scheme, such as Trada or Firas.

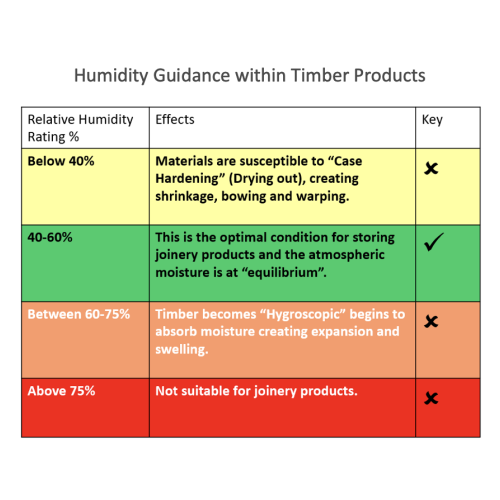

Joinery products should always be installed after Wet Trades have finished and the building moisture levels have returned to normal.

Joinery installed in areas where moisture levels are high are susceptible to hygrothermal (Moisture & Heat) effects. These conditions can result in product distortion and warping or excessive shrinkage.

The building/area relative humidity should fall between 40-60% RH for internal joinery products.

Hanson and Beards doorset products are supplied in a black shrink wrap but should never be stored outside or in areas with high levels of moisture or humidity.

Products should ideally be stored for 2 to 3 weeks close to the installation area or in a location with the same ambient conditions to allow the product to stabilise before fitting.

Products should not be stacked directly onto the floor. Doorsets should be stacked up to a maximum height of 1200mm with a minimum of 3x door width bearers set equally along the product length to prevent distortion/deformation

Doors should not be stood upright on their ends, this causes distortion making the doorsets inoperable.

Q-Mark Fire Door Maintenance Scheme

- Ensure the product’s service life is maximised through correct maintenance.

- Ensure the product’s fire resistance capabilities and independent third-party certification are maintained.

- Provide peace of mind that the maintainer is suitably qualified, and the certification chain is never broken.

- Only Q-Mark approved and acceptable repair techniques are employed.